JeepSmoker

Member

Not sure of other models of Pit Boss horizontal smokers, but the Lockhart leaves me less than satisfied with the way pellets feed down to the auger! I think the engineers/promotional staff may have been more interested in quantity of pellets loaded than the way they feed to the auger. I don't want to have to get up 3 or 4 times a night to push pellets to the bottom and have tried a number of different fixes with varying degrees of success. I've searched all kinds of forums for solutions and some have worked but none well. For anyone with the same problem, I'll share these with you and tell you what has worked for me.

1. Wax the hopper with auto wax. The Lockhart should not have a texture-painted hopper. It should be as smooth as a baby's bottom. Waxing it didn't help much!

2. Glued PTFE (Teflon) paper to the sloped surfaces of the hopper. This helped some, was a royal pain to cut it to fit, and as everyone knows, nothing is supposed to stick to a non-stick surface! Contact cement seemed to work the best, the results better but marginal.

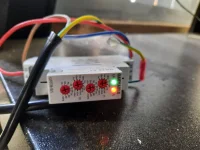

3. Time to get serious. I read on one foru!!m where a guy jokingly suggested taping the biggest vibrator you could get from an adult store to the hopper...a real conversation piece but not really practical . I ordered a variable industrial machine vibrator and variable delay time from Amazon, attached it to the inner surface of the OUTSIDE of the hopper bin, and set the timer to run for 10 seconds every hour. Works perfectly! No more overnight cook worries!

. I ordered a variable industrial machine vibrator and variable delay time from Amazon, attached it to the inner surface of the OUTSIDE of the hopper bin, and set the timer to run for 10 seconds every hour. Works perfectly! No more overnight cook worries!

My biggest concern was the vibration affecting the smoker components mounted in the area. After RTV'ing all the wire connections (because of previous connection failures), I have high hopes for the longevity of this setup. If anyone shows any interest in this, I'll post pics and part #'s of what was used in the mod.

Cheers, ALL

1. Wax the hopper with auto wax. The Lockhart should not have a texture-painted hopper. It should be as smooth as a baby's bottom. Waxing it didn't help much!

2. Glued PTFE (Teflon) paper to the sloped surfaces of the hopper. This helped some, was a royal pain to cut it to fit, and as everyone knows, nothing is supposed to stick to a non-stick surface! Contact cement seemed to work the best, the results better but marginal.

3. Time to get serious. I read on one foru!!m where a guy jokingly suggested taping the biggest vibrator you could get from an adult store to the hopper...a real conversation piece but not really practical

My biggest concern was the vibration affecting the smoker components mounted in the area. After RTV'ing all the wire connections (because of previous connection failures), I have high hopes for the longevity of this setup. If anyone shows any interest in this, I'll post pics and part #'s of what was used in the mod.

Cheers, ALL